Feldspar is the most common mineral in the Earth's crust and has even been found on the moon and in meteorites. It is increasingly used in glassmaking, the ceramic industry, as well as in the chemical, abrasive, and electrode industries.

Feldspar Crushing And Grinding Equipment

The selection of feldspar crushing and grinding equipment is an indispensable part of the feldspar processing process.

Feldspar crushers mainly include feldspar jaw crusher, feldspar impact crusher and feldspar cone crusher. In the feldspar grinding process, ball mill is the most common feldspar grinding machine. Raymond mill, high pressure mill and ultra-fine mill are also widely used in feldspar grinding plants.

Feldspar mill is redefining the standard of feldspar processing with its excellent performance and efficient processing capacity. Our feldspar mill is not only able to crush feldspar blocks into smaller sizes, but also can reduce the size to below 5-20mm during the grinding process, meeting the fine demands of feldspar powder in different industrial fields.

Feldspar processing technology

01 Primary crushing using a jaw crusher, followed by secondary crushing using a cone crusher.

02 Feldspar grinding equipment, also known as a feldspar grinder, pulverizes or crushes feldspar to the required fineness.

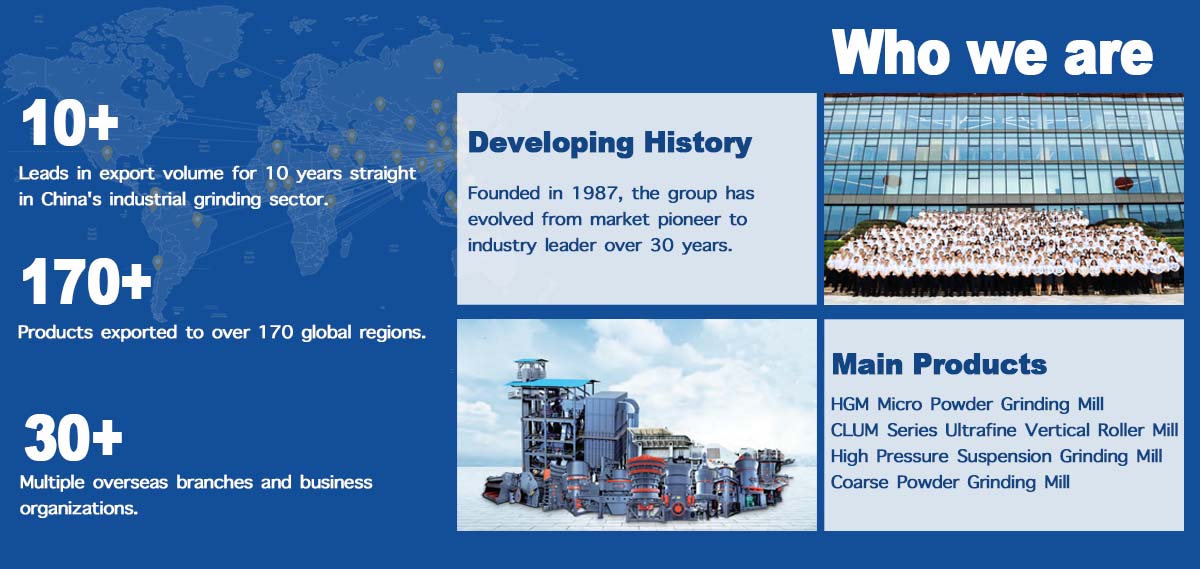

Clirik, as a leading provider of feldspar grinding solutions, we are committed to providing the most suitable feldspar grinding solution for each method and application. Our new feldspar grinding mill not only improves production efficiency, but also ensures product consistency and high quality. This is a huge advantage for industries such as chemical, abrasive, electrode industry, etc. that have strict requirements on material purity and fineness.