Feldspar grinding mill refers to a machine that can meet the needs of feldspar grinding. There are many types and functions of this machine, so it is necessary to choose. Although the material of feldspar has been determined, the specific production needs are different, including different output requirements and product specifications. So what should we base our choice of machine on?

01 Material Properties

Understand the characteristics of feldspar, as it's crucial for choosing the right grinder.

02 Production Needs

Define the quality and quantity requirements of the finished feldspar to match the grinder's capabilities.

03 Operation and Energy Consumption

Consider the simplicity of operation and the energy efficiency of the grinding machine.

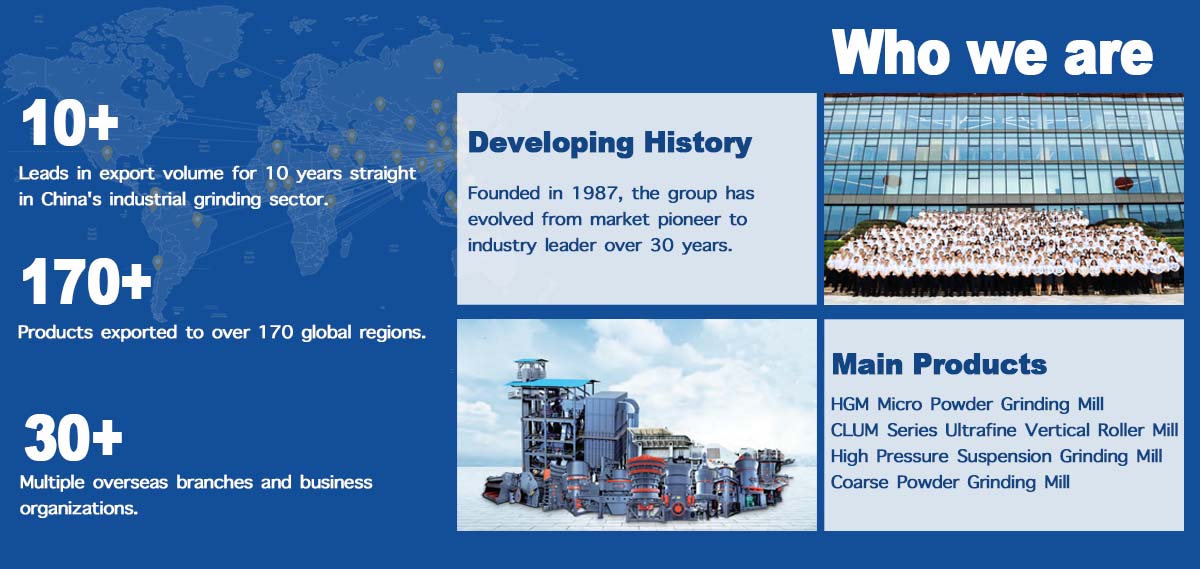

When it comes to choosing a feldspar grinding mill, Clirik's products are the first choice in the market due to their excellent performance and features. Here are some significant advantages of Clirik Feldspar Mill that make it an ideal choice for you:

High Efficiency and Energy Saving

Clirik's feldspar grinding mill has twice the output of airflow mills, stirrer mills and ball mills when the final product fineness and motor power are the same. This means you can achieve more output with the same energy consumption, significantly reducing production costs.

Consumable Parts Have Long Service Life

The grinding roller and grinding ring are forged from special materials, which greatly improves the service life. When the fineness of the finished material is the same, the service life of the wear parts of the impact crusher and turbine pulverizer is 2-5 times longer, generally up to more than one year. When the grinding mill processes calcium carbonate and calcite, its service life can reach 2-5 years.

Complete Technical Parameters

Clirik offers various models of feldspar grinding mills to meet the needs of different production capacities. The output can be adjusted from 0.4-7.5 tons per hour, and the particle size of fine powder finished products between 200-3000 mesh can be adjusted arbitrarily.

Service Guarantee

Clirik's project manager tracks the entire process from equipment selection to capacity optimization to maintenance. Clirik provides you with technical support and avoids risks.

Clirik feldspar mill stands out among many mill brands for its advantages such as high efficiency, durability, safety and environmental protection. Choosing Clirik feldspar mill, you will enjoy high-quality products and services, which will provide strong guarantee for your production efficiency and product quality.